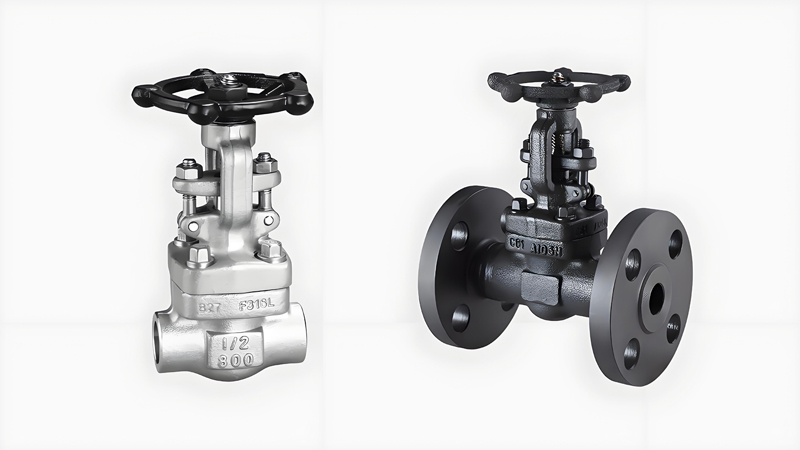

फोर्ज्ड स्टील गेट वाल्व: चुनौतीपूर्ण उद्योगों के लिए उच्च-प्रदर्शन समाधान

फोर्ज्ड स्टील गेट वाल्व औद्योगिक पाइपिंग प्रणालियों के महत्वपूर्ण घटक हैं, जिन्हें अत्यधिक दबाव, तापमान और संक्षारक वातावरण को सहन करने के लिए डिज़ाइन किया गया है। यह लेख फोर्ज्ड स्टील गेट वाल्व क्या हैं, उनके लाभ, अनुप्रयोग और तकनीकी विशिष्टताओं के साथ-साथ इन्हें चुनने के कारणों की भी पड़ताल करता है।चीनी जाली इस्पात गेट वाल्व निर्माताइससे विश्वसनीयता और लागत-दक्षता सुनिश्चित होती है।

फोर्ज्ड स्टील गेट वाल्व क्या होता है?

A जाली स्टील गेट वाल्वयह एक प्रकार का वाल्व है जिसे फोर्जिंग द्वारा निर्मित किया जाता है, जिसमें स्टील को उच्च ताप और दबाव में संपीड़ित और आकार दिया जाता है। यह विधि धातु की संरचनात्मक अखंडता को बढ़ाती है, जिससे कास्ट किए गए वाल्वों की तुलना में यह अधिक मजबूत, टिकाऊ और रिसाव-प्रतिरोधी बनता है।

इसके प्रमुख घटकों में वेज के आकार का गेट, स्टेम और बॉडी शामिल हैं, जिन्हें उच्च तनाव वाली प्रणालियों में सटीक प्रवाह नियंत्रण के लिए डिज़ाइन किया गया है।

फोर्ज्ड स्टील गेट वाल्व के फायदे

1. बेहतरीन मजबूती और टिकाऊपनफोर्ज्ड स्टील उच्च तन्यता शक्ति प्रदान करता है, जो इसके लिए आदर्श है।क्लास 800 फोर्ज्ड स्टील गेट वाल्व(800 पीएसआई के लिए रेटेड)।

2. रिसाव-मुक्त प्रदर्शन: सख्त सीलिंग महत्वपूर्ण अनुप्रयोगों में अनियंत्रित उत्सर्जन को कम करती है।

3. उच्च तापमान प्रतिरोधयह 1,000°F (538°C) तक के तापमान को सहन कर सकता है।

4. संक्षारण प्रतिरोध: भाप, तेल, गैस और आक्रामक रसायनों के साथ संगत।

5. बहुमुखी कनेक्शन: उपलब्ध हैएसडब्ल्यू (सॉकेट वेल्ड), बीडब्ल्यू (बट वेल्ड), औरएनपीटी जाली स्टील गेट वाल्वलचीली स्थापना के लिए।

फोर्ज्ड स्टील गेट वाल्व के अनुप्रयोग

फोर्ज्ड स्टील गेट वाल्व का व्यापक रूप से उपयोग निम्नलिखित में किया जाता है:

- तेल और गैस पाइपलाइनें

- विद्युत उत्पादन संयंत्र

- रासायनिक प्रसंस्करण इकाइयाँ

- उच्च दाब वाली भाप प्रणालियाँ

- रिफाइनरी और पेट्रोकेमिकल सुविधाएं

सामान्य आकारों में शामिल हैं1/2 इंच जाली स्टील गेट वाल्वकॉम्पैक्ट सिस्टम के लिए और1 1/2 जाली स्टील गेट वाल्वबड़ी पाइपलाइनों के लिए।

तकनीकी विशिष्टताएँ: दबाव, आकार और तापमान

- दबाव रेटिंग: श्रेणी 150 से श्रेणी 2500 तक,क्लास 800 फोर्ज्ड स्टील गेट वाल्वभारी-भरकम कार्यों के लिए यह एक लोकप्रिय विकल्प है।

- आकारमानक आकार 1/2″ से 24″ तक होते हैं, साथ ही कस्टम विकल्प भी उपलब्ध हैं।

- तापमान की रेंज: -20°F से 1,000°F (-29°C से 538°C), जो ASTM A105 या A182 जैसे मटेरियल ग्रेड पर निर्भर करता है।

चीनी फोर्ज्ड स्टील गेट वाल्व निर्माताओं को क्यों चुनें?

वाल्व निर्माण में चीन एक वैश्विक नेता के रूप में उभरा है, जो निम्नलिखित सुविधाएं प्रदान करता है:

1. किफायती मूल्य निर्धारण: प्रतिस्पर्धीजाली स्टील गेट वाल्व की कीमतेंगुणवत्ता से समझौता किए बिना।

2. उन्नत उत्पादन क्षमताएँ: सटीक फोर्जिंग और परीक्षण के लिए अत्याधुनिक सुविधाएं।

3. अनुकूलनआकार के अनुसार अनुकूलित समाधान (उदाहरण के लिए,1 1/2 जाली स्टील गेट वाल्व), दबाव वर्ग और कनेक्शन प्रकार।

4. वैश्विक प्रमाणपत्रएपीआई, एएनएसआई और आईएसओ मानकों का अनुपालन।

अग्रणीचीनी जाली इस्पात गेट वाल्व कारखानेविशेषज्ञता को उत्पादन क्षमता के साथ मिलाकर, थोक ऑर्डर की समय पर डिलीवरी सुनिश्चित की जाती है।

SW, BW और NPT जाली स्टील गेट वाल्व

- एसडब्ल्यू (सॉकेट वेल्ड): छोटे व्यास और उच्च दबाव वाली प्रणालियों के लिए आदर्श।

- बीडब्ल्यू (बट वेल्ड)इसका उपयोग स्थायी, उच्च गुणवत्ता वाले पाइपिंग नेटवर्क में किया जाता है।

- एनपीटी (नेशनल पाइप थ्रेड): कम दबाव और आसान स्थापना वाले परिदृश्यों के लिए उपयुक्त।

निष्कर्ष

सुरक्षा और दक्षता को प्राथमिकता देने वाले उद्योगों के लिए, विशेष रूप से कठिन परिस्थितियों में, जाली इस्पात के गेट वाल्व अपरिहार्य हैं। चाहे आपको आवश्यकता हो...क्लास 800 फोर्ज्ड स्टील गेट वाल्वकॉम्पैक्ट1/2 इंचमॉडल, या कस्टम ब्लैक एंड व्हाइट/सॉफ़्टवेयर डिज़ाइन,चीनी जाली इस्पात गेट वाल्व निर्माताबेजोड़ गुणवत्ता और किफायती दाम प्रदान करना।

प्रतिस्पर्धी के लिएजाली स्टील गेट वाल्व की कीमतेंऔर अनुकूलित समाधानों के लिए, अपनी परिचालन संबंधी मांगों को पूरा करने के लिए चीन में विश्वसनीय आपूर्तिकर्ताओं के साथ साझेदारी करें।

पोस्ट करने का समय: 7 मार्च 2025